1/6/2022

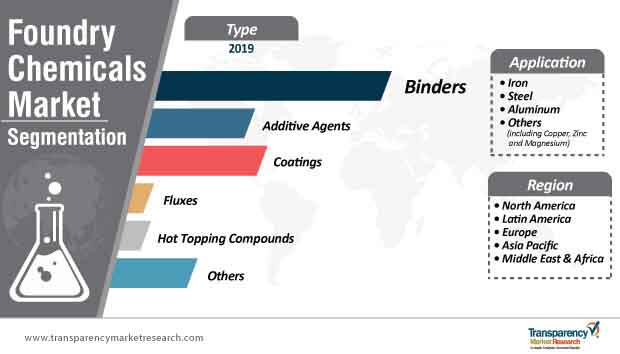

Foundry Chemicals Market by Development, Trends, and Forecast (2019-2027)

5/9/2022

Foundry Chemicals Market: Key Highlights

- The global foundry chemicals market was valued at ~US$ 2.2 Bn in 2018, and is anticipated to expand at a CAGR of ~3% during the forecast period.

- The global foundry chemicals market is driven by the rise in the demand for lightweight materials in the automotive industry.

- The foundry industry in Asia Pacific is concentrated in China, India, and Japan. India is anticipated to lead the demand for foundry chemicals in Asia Pacific during the forecast period. The foundry industry in India is expanding at a rapid pace and this is estimated to boost the foundry chemicals market in the country during the forecast period.

Request A Sample of Foundry Chemicals Market - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=33776

Key Drivers of the Foundry Chemicals Market

- Aluminum cast parts are light in weight and have the strength of steel. The appearance and esthetic value of aluminum-made parts is also superior to that of other metal alloys. Also, aluminum cast parts are cheaper, and, as such, end consumers can buy high quality metal products at affordable prices. Castings made from aluminum are versatile, corrosion resistant, and can be used for different purposes. These qualities allow manufacturers to produce multiple products using aluminum parts. The finished products also have a longer lifespan, thus giving consumers more value.

- The Middle East & Africa offers immense potential for investors operating in the foundry chemicals industry. The market size is small in the region; however, there exists vast potential for casting products due to the growth in the automotive industry.

Enquiry Before Buying: https://www.transparencymarketresearch.com/sample/sample.php?flag=EB&rep_id=33776

Cast Iron to Offer Attractive Opportunities

- In terms of metal, cast iron was a highly attractive segment of the global foundry chemicals market in 2018. The segment is expected to maintain its attractiveness in the foundry chemicals market during the forecast period, due to the easy availability and low production cost of these casting components.

- Cast iron is a cost-efficient and strong metal. Hence, it is used in the production of components that are exposed to extreme mechanical stress.

- Aluminum was a rapidly expanding segment of the global foundry chemicals market in 2018. Aluminum castings are prominently employed in automotive parts. Rise in the trend of using aluminum-cast automotive parts, led by their light weight, is expected to boost the demand for aluminum foundries in near future. This, in turn, is estimated to drive the aluminum segment of the foundry chemicals market during the forecast period.

Purchase A Report- https://www.transparencymarketresearch.com/checkout.php?rep_id=33776<ype=S

Adverse Effects of Foundry Industry on Environment likely to Hamper Market

- Stringent environmental regulations imposed on the foundry industry are adversely affecting the consumption of foundry chemicals across the globe. Environmental regulations for foundries are primarily related to the disposal of waste gases, wastewater, and mineral residues.

- Raw materials such as additives and fuels are used during the production of casting parts. This leads to the emission of harmful gases. Dust from the process may contain metals and metal oxides. During the melting process, elements evaporate and tiny metal dust particles are released. Metal particles appear during the final processing.

- BTX (benzene toluene and xylene) and phenolic emissions are associated with foundry operations, along with harmful gases. Thus, the adverse environmental effects of gases and chemicals are expected to hamper the global foundry chemicals market during the forecast period.

Other articles and publications:

Composite Cylinder Market Future Growth, Share, Trends And Forecast (2019-2027)- An Exclusive Report

Composite Cylinder Market Future Growth, Share, Trends And Forecast (2019-2027)- An Exclusive Report

Composite Cylinder Market Future Growth, Share, Trends And Forecast (2019-2027)- An Exclusive Report

Aquaculture Chemicals Market Supply Chain Analysis and forecast to 2027

2/14/2022

FTNF Aromas Market Size, Share, Growth, Trends, and Forecast 2019-2027

3/10/2022

Fuel Ethanol Market by Development, Trends, and Forecast 2029

1/31/2022

Precious Metal Plating Chemicals Market Applications, Trends and Forecast by 2027

2/8/2022

Oxoacetic Acid Market Growth, Trends, and Forecast 2019-2027

12/8/2021

Articles and publications of other companies:

5 Tips for Creating a Mobile-Friendly Ecommerce Website

8/1/2021

Are you fond of collecting guns for prestige or do you need guns for your safety because you prioritize safety than anything?

2/22/2021

You can forget about waiting on queues to purchase what you've managed to get. Buying clothes online is simple and saves a large amount of time friend of yours who's far from the area of yours.

3/9/2021

Business details

- +1 (518) 618-1030

- State Tower, 90 State Street, Suite 700, Albany NY - 12207, United States

We are the ‘difference’ between success and failure in business. It can’t get simpler than this in explaining what we are. A market research company, our reports and expertise into and outside your bu